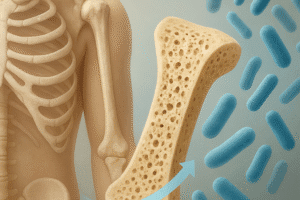

Recent developments in additive manufacturing have propelled the field of bone tissue engineering into an exciting new era. Researchers and clinicians are leveraging 3D printing technologies to fabricate complex structures that mimic the hierarchical architecture of native bone. These scaffolds provide support, guide cell growth, and ultimately promote tissue regeneration. This article explores key advancements in materials science, biological functionality, clinical translation, and future challenges related to 3D-printed bone scaffolds.

Material Innovations for Enhanced Scaffold Performance

Selecting the right material is pivotal for scaffold efficacy. Early designs relied on ceramics like hydroxyapatite and tricalcium phosphate due to their high biocompatibility and similarity to bone mineral. However, their inherent brittleness limited clinical applications. Recent strategies focus on composites and novel polymers to balance strength and flexibility.

Composite Formulations

- Polymer-Ceramic Blends: Combining biodegradable polymers such as polylactic acid (PLA) with ceramic fillers enhances mechanical strength while preserving osteoconductivity.

- Nanocomposite Scaffolds: Incorporating nanoparticles of silica or bioactive glass results in improved surface roughness, favoring cell attachment and osteointegration.

- Metallic Reinforcement: Titanium or magnesium microstructures embedded within polymer matrices offer load-bearing capacity without compromising biodegradability.

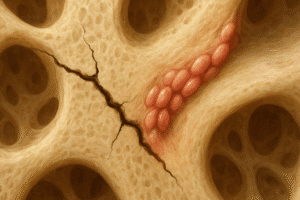

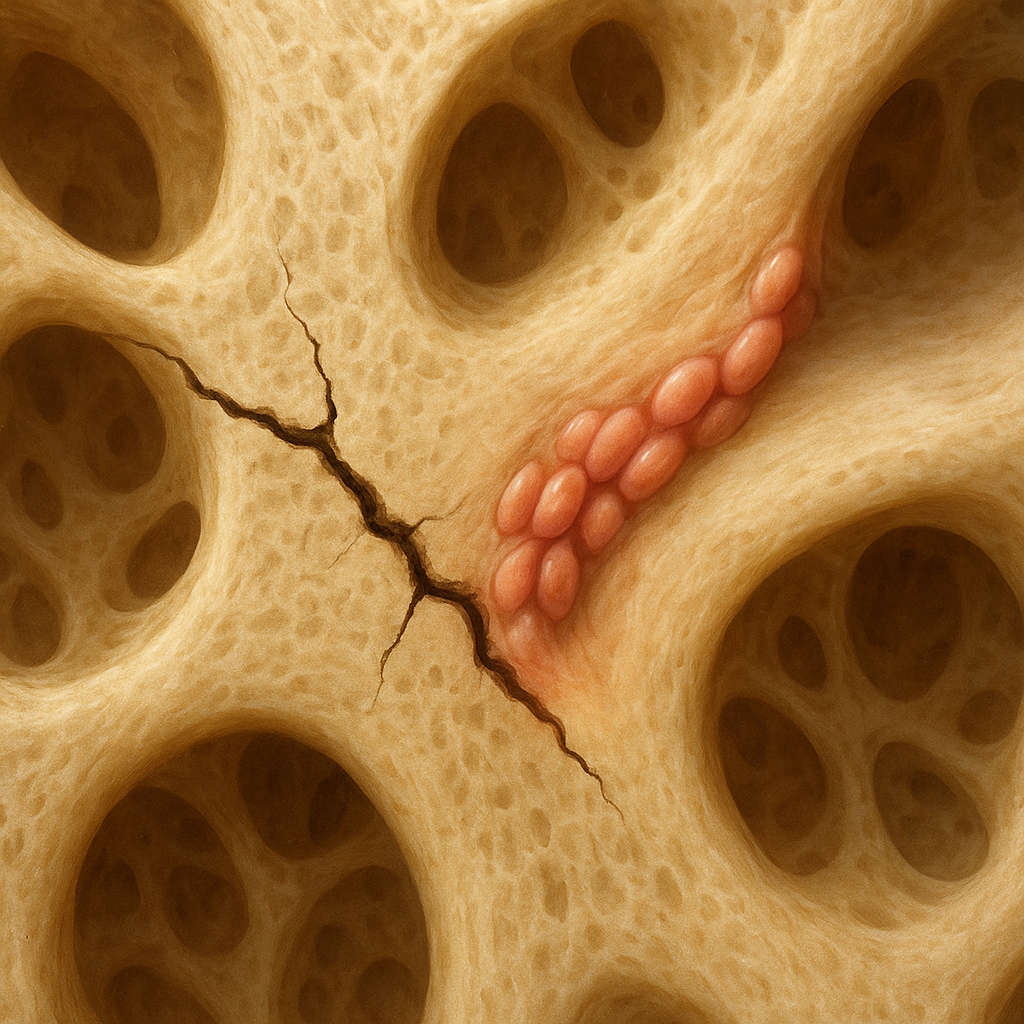

Architectural Control and Porosity

Precise modulation of porosity is critical to ensure nutrient diffusion, vascular ingrowth, and mechanical stability. Advanced printing methods now allow multi-scale pore networks:

- Macropores (>300 μm): Facilitate blood vessel infiltration and promote angiogenesis.

- Micropores (10–100 μm): Increase surface area for protein adsorption and improve cell–material interactions.

- Gradient Porosity: Mimics cancellous-to-cortical bone transitions, providing load distribution akin to natural bone.

Biological Functionality and Cellular Integration

To achieve functional bone regeneration, scaffolds must not only support mechanical loads but also orchestrate biological processes. Integrating bioactive factors and living cells into the printing process has transformed scaffold design from passive supports to dynamic regenerative platforms.

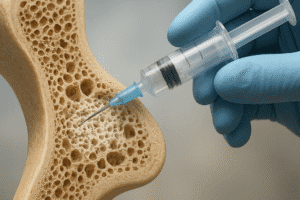

Growth Factors and Drug Delivery

Embedding growth factors such as bone morphogenetic proteins (BMPs) and vascular endothelial growth factor (VEGF) within scaffolds creates a sustained-release system that accelerates osteogenesis. Microcapsules and nanocarriers loaded with these proteins can be printed directly into scaffold pores, offering localized therapeutic effects.

Stem Cell-Loaded Constructs

Seeding scaffolds with mesenchymal stem cells (MSCs) enhances tissue regeneration by providing a source of osteoprogenitors. Innovative approaches include:

- Pre-differentiation: MSCs are coaxed towards the osteogenic lineage before printing to boost mineral deposition post-implantation.

- Co-culture Systems: Combining MSCs with endothelial cells fosters vessel formation and rapid angiogenesis, ensuring cell survival in large constructs.

- Bioprinting Techniques: Layer-by-layer deposition of cell-laden bioinks enables precise spatial placement of cell populations within complex geometries, enhancing customization.

Clinical Translation and Regulatory Considerations

Bridging the gap between laboratory innovation and bedside application requires navigating stringent regulatory pathways and ensuring reproducibility. Several clinical trials now evaluate the safety and efficacy of 3D-printed scaffolds in bone defect repairs.

Standards and Quality Control

Regulatory agencies demand detailed characterization of scaffold properties, including:

- Material Purity: Verification of polymer and ceramic constituents to minimize immunogenic responses.

- Mechanical Testing: Assessments under physiological loading conditions to validate mechanical strength.

- Degradation Kinetics: In vitro and in vivo studies to confirm predictable biodegradability matching new tissue formation rates.

Case Studies in Orthopedics

Recent pilot studies demonstrate successful implantation of patient-specific scaffolds in critical-sized defects of the femur and mandible. Outcomes include robust bone ingrowth and restored function without adverse events, highlighting the promise of personalized 3D-printed implants.

Future Directions and Emerging Technologies

The next frontier in scaffold research explores integration with smart systems and advanced fabrication methods. Emphasizing multifunctional capabilities and automation will drive further improvements in patient care.

Smart Scaffolds and Biosensing

Embedding sensors within scaffolds can provide real-time feedback on mechanical loading, pH changes, and local biochemical markers. This data enables clinicians to monitor healing progress non-invasively and adjust rehabilitation protocols accordingly.

Advanced Bioprinting Modalities

Techniques such as stereolithography and multiphoton polymerization offer submicron resolution for printing microvasculature and trabecular-like architectures. These high-fidelity approaches aim to precisely replicate the complexity of native bone at multiple scales.

Artificial Intelligence in Design Optimization

Machine learning algorithms are being employed to optimize scaffold geometries based on patient-specific imaging data. Predictive models can suggest ideal pore sizes, gradient distributions, and material compositions to maximize regenerative outcomes.

Challenges and Considerations

Despite rapid progress, several hurdles remain. Long-term biocompatibility studies are needed to assess immune reactions to novel materials and degradation by-products. Additionally, scalability and cost-effectiveness must be addressed to make these advanced therapies accessible in diverse healthcare settings.

As technology continues to evolve, multidisciplinary collaboration among materials scientists, biologists, engineers, and clinicians will be essential to translate 3D-printed bone scaffolds from experimental prototypes to standard-of-care solutions. The convergence of innovative materials, precise fabrication, and biological insights promises to revolutionize bone regeneration and improve patient outcomes worldwide.