Bone tissue engineering is poised to revolutionize the management of skeletal defects, offering strategies that fuse biology, materials science, and engineering. As musculoskeletal disorders and traumatic bone injuries continue to burden healthcare systems, the pursuit of robust, scalable, and functional bone substitutes grows ever more critical. This article examines key advancements in biomaterials, cellular therapies, vascularization, and translational challenges, while highlighting emerging technologies that will define the next decade of innovation.

Biomaterials and Scaffold Innovations

Designing a successful scaffold requires careful consideration of biocompatibility, mechanical strength, degradation rate, and the capacity to guide cell behavior. Recent progress in 3D printing platforms has enabled the fabrication of patient-specific architectures with controlled pore size, interconnectivity, and overall geometry. Innovations in nanotechnology have introduced bioactive nanoparticles—such as nano-hydroxyapatite and bioactive glass—that can be embedded within polymer matrices to enhance osteoconductivity. Composite scaffolds combine synthetic polymers like polycaprolactone (PCL) or polylactic-co-glycolic acid (PLGA) with natural polymers (collagen, chitosan) to achieve an optimal balance between strength and bioactivity.

- Natural biomaterials: collagen, silk fibroin, gelatin

- Synthetic polymers: PCL, PLGA, polyethylene glycol (PEG)

- Ceramic components: nano-hydroxyapatite, tricalcium phosphate (TCP)

- Composite scaffolds: hybrid networks for tailored resorption

Advanced techniques such as electrospinning and coaxial extrusion further allow hierarchical micro- and nano-scale features that mimic native bone extracellular matrix. By integrating growth factor–loaded microspheres or peptide‐functionalized surfaces, these scaffolds can actively modulate cell adhesion and differentiation, guiding progenitor cells toward osteoblastic lineages.

Cellular Strategies and Molecular Regulation

Cell-based therapies are at the core of bone regeneration. Mesenchymal stem cells (MSCs) derived from bone marrow, adipose tissue, or umbilical cord blood have demonstrated robust potential in preclinical models. These cells can secrete trophic factors, modulate inflammation, and directly contribute to new bone formation through osteogenesis. Induced pluripotent stem cells (iPSCs) offer an autologous source of osteoprogenitors, though safety concerns about genomic stability remain under investigation.

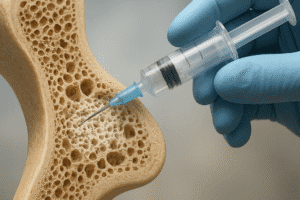

Precise spatiotemporal delivery of growth factors such as bone morphogenetic proteins (BMP-2, BMP-7) and vascular endothelial growth factor (VEGF) accelerates differentiation and vascularization within the construct. Controlled-release systems—ranging from microspheres to hydrogel depots—ensure that bioactive signals are presented in physiological doses, reducing the risks associated with supraphysiological administration.

- Paracrine signaling: harnessing the secretome for immunomodulation

- Gene therapy approaches: transient transfection of osteogenic genes

- Co-culture systems: endothelial cells and MSCs for synergistic effects

Engineering Vascularized Bone Constructs

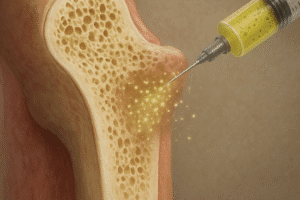

One of the biggest challenges in large bone defect repair is establishing a functional blood supply. Without timely perfusion, implanted tissues suffer necrosis and fail to integrate. Recent approaches focus on prevascularizing scaffolds via:

- Microfluidic bioreactors that simulate physiological shear stress and nutrient flow.

- Endothelial cell networks co-cultured with osteoprogenitors to form capillary-like structures.

- Angiogenic factors tethered to scaffold surfaces to recruit host vasculature.

These strategies aim to enhance tissue integration by providing immediate perfusion following implantation. Biofabrication platforms now allow the simultaneous deposition of cell-laden bioinks and sacrificial materials, creating microchannels that later become perfusable vessels. By combining perfusion bioreactors with real-time imaging, researchers can monitor vessel formation and adjust culture parameters dynamically.

Clinical Translation and Regulatory Challenges

Despite promising preclinical results, few bone engineering products have reached widespread clinical use. Key hurdles include:

- Scalability: manufacturing patient-specific grafts under good manufacturing practice (GMP) conditions.

- Regulatory frameworks: navigating the classification of combined products (cells plus devices) and meeting safety standards.

- Cost-effectiveness: balancing the high costs of cell culture, bioreactors, and custom scaffolds against clinical benefit.

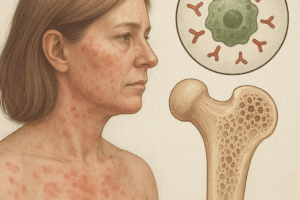

Bridging the gap between bench and bedside requires standardized potency assays, robust in vivo models, and collaborative consortia involving academia, industry, and regulatory agencies. Personalized implants must demonstrate consistent performance across diverse patient populations, accounting for variables such as age, comorbidities, and defect size.

Future Perspectives in Regenerative Orthopedics

Emerging Technologies

The convergence of artificial intelligence, machine learning, and high-throughput experimentation will streamline scaffold design. Predictive algorithms can optimize material composition and structural features to meet specific biomechanical requirements. Additionally, the integration of sensors within constructs will facilitate real-time monitoring of pH, oxygen tension, and mechanical loading, enabling adaptive culture conditions.

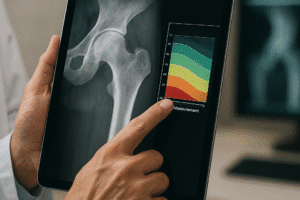

Personalized Therapies

Patient-specific therapeutics will rely on advanced imaging data to generate digital twins of bone defects. Computer-aided design (CAD) combined with 3D printing and bioprinting will yield implants that conform precisely to anatomical contours. Gene-editing tools such as CRISPR-Cas9 may further enhance cellular function, promoting accelerated healing and reducing immune rejection. Ultimately, the synergy between engineering and cell biology promises a new era of regenerative medicine where complex skeletal reconstructions become routine, safe, and cost-effective.