The use of 3D printing in bone reconstruction has revolutionized the field of medicine, offering innovative solutions for complex surgical challenges. This technology allows for the creation of customized implants and prosthetics that can significantly improve patient outcomes. As the demand for effective bone reconstruction techniques continues to grow, 3D printing stands out as a promising approach that combines precision, efficiency, and personalization.

Understanding 3D Printing Technology

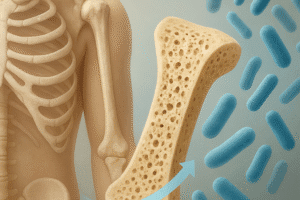

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects from a digital file. This technology has evolved rapidly over the past few decades, moving from simple prototypes to complex structures used in various industries, including healthcare. In the context of bone reconstruction, 3D printing involves the layer-by-layer deposition of materials to form implants that can mimic the natural structure of bone.

The Process of 3D Printing in Bone Reconstruction

The process of 3D printing for bone reconstruction typically involves several key steps:

- Digital Imaging: The first step is to obtain detailed images of the patient’s bone structure using techniques such as CT scans or MRIs. These images provide the necessary data to create a precise digital model of the bone.

- 3D Modeling: Using specialized software, the digital images are transformed into a 3D model. This model can be customized to fit the specific needs of the patient, including size, shape, and structural integrity.

- Material Selection: Various biocompatible materials can be used in 3D printing, including polymers, metals, and ceramics. The choice of material depends on the specific requirements of the reconstruction, such as strength, flexibility, and integration with existing bone.

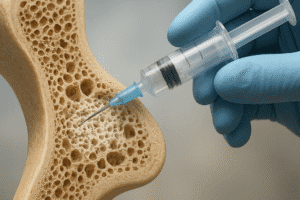

- Printing: The 3D printer then creates the implant layer by layer, following the specifications of the digital model. This process can take several hours to days, depending on the complexity and size of the implant.

- Post-Processing: After printing, the implant may require additional processing, such as sterilization or surface treatment, to ensure it is safe and ready for surgical implantation.

Advantages of 3D Printing in Bone Reconstruction

The integration of 3D printing into bone reconstruction offers numerous advantages:

- Customization: One of the most significant benefits is the ability to create patient-specific implants. This customization leads to better fit and function, reducing the risk of complications and improving recovery times.

- Reduced Surgical Time: With pre-fabricated implants, surgeons can perform procedures more efficiently, leading to shorter operating times and less time under anesthesia for patients.

- Cost-Effectiveness: Although the initial investment in 3D printing technology can be high, the long-term savings from reduced surgical complications and shorter hospital stays can make it a cost-effective solution.

- Enhanced Biocompatibility: 3D printed implants can be designed to promote better integration with the surrounding bone, leading to improved healing and functionality.

Applications of 3D Printing in Bone Reconstruction

3D printing has found applications in various areas of bone reconstruction, including trauma surgery, orthopedic surgery, and craniofacial reconstruction. Each of these fields benefits from the unique capabilities of 3D printing technology.

Trauma Surgery

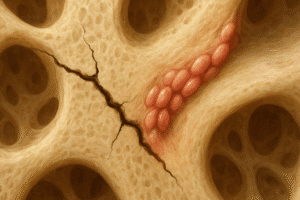

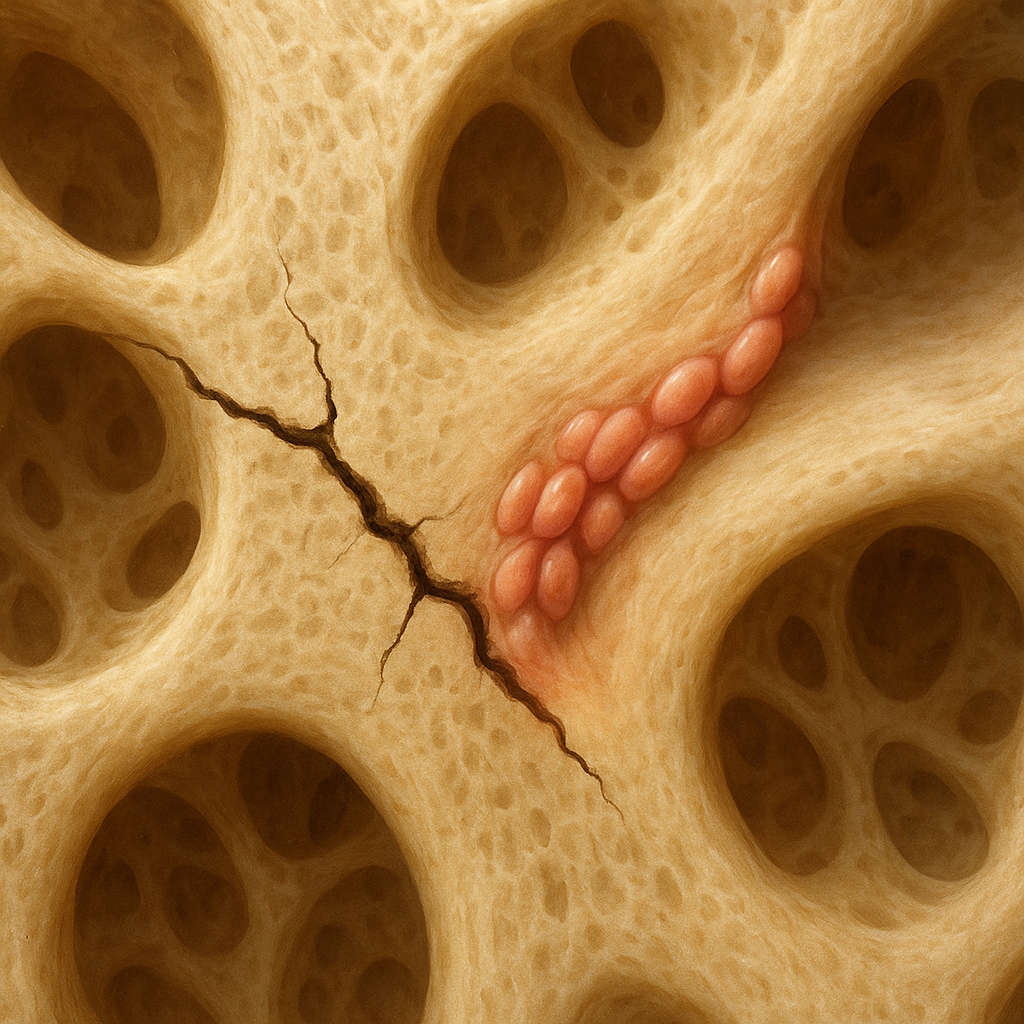

In trauma surgery, 3D printing is used to create implants for patients who have suffered severe bone fractures or injuries. Traditional methods of bone reconstruction often involve the use of metal plates and screws, which may not provide the best fit for complex fractures. With 3D printing, surgeons can design implants that match the exact contours of the patient’s bone, leading to better stabilization and healing.

Orthopedic Surgery

Orthopedic surgeons are increasingly using 3D printing to create custom joint replacements and bone grafts. For example, patients with osteoarthritis may require knee or hip replacements that are tailored to their specific anatomy. 3D printed implants can provide a more natural fit, improving mobility and reducing pain post-surgery.

Craniofacial Reconstruction

Craniofacial reconstruction involves the repair of skull and facial bone defects, often due to congenital conditions, trauma, or tumors. 3D printing allows for the creation of intricate implants that can restore both function and aesthetics. Surgeons can design implants that not only fit perfectly but also replicate the natural appearance of the patient’s facial structure.

Challenges and Future Directions

Despite the many advantages of 3D printing in bone reconstruction, there are still challenges that need to be addressed. These include regulatory hurdles, material limitations, and the need for further research to optimize the technology for clinical use.

Regulatory Challenges

The regulatory landscape for 3D printed medical devices is still evolving. Each country has its own set of regulations governing the approval of medical implants, and navigating these can be complex. Manufacturers must ensure that their products meet safety and efficacy standards before they can be used in clinical settings.

Material Limitations

While there are many materials available for 3D printing, not all are suitable for bone reconstruction. Researchers are continually exploring new biocompatible materials that can better mimic the properties of natural bone, such as porosity and mechanical strength. The development of these materials is crucial for the future success of 3D printing in this field.

Research and Development

Ongoing research is essential to fully realize the potential of 3D printing in bone reconstruction. Studies are needed to evaluate the long-term outcomes of 3D printed implants, including their durability, integration with existing bone, and overall patient satisfaction. Additionally, advancements in printing technology, such as bioprinting, may open new avenues for creating living tissue constructs that can further enhance bone healing.

Conclusion

The use of 3D printing in bone reconstruction represents a significant advancement in medical technology. By enabling the creation of customized implants that are tailored to the unique needs of each patient, 3D printing has the potential to improve surgical outcomes and enhance the quality of life for individuals with bone defects or injuries. As the technology continues to evolve and overcome existing challenges, it is likely that 3D printing will play an increasingly important role in the future of orthopedic and reconstructive surgery.